For EPC Contractors

We offer deaerators with instrumentation, providing very fast response times and involvement, already during the initial offer phase.

For Workshops

We offer a deaerator engineering package, with basic design drawings and process guarantees, with the key internal parts.

For End Users

We design a replacement unit or deliver spare parts to your existing deaerator, tailored to your needs.

Deaerators. With the best design available.

BS Deaerators offers a wide range of deaerator solutions carefully designed to meet the diverse needs of customers such as power stations, industrial plants and engineering companies. We can provide expert advice on the ideal deaerator system to ensure longevity and efficiency for your water-steam cycle.

A feedwater tank for your boiler system.

The central component of many industrial processes is a boiler. Boilers provide essential thermal energy for a range of applications by generating steam from feed water. However, the problem of dissolved gases and corrosive substances in the feed water must be solved to ensure the longevity and optimum lifetime of the entire system. With a deaerator, we offer a physical-thermal solution to remove oxygen and other dangerous impurities from the water and thus prevent corrosion in the water-steam cycle.

A deaerator is sometimes also referred to as a feed water tank and has three basic functions: Removing oxygen and CO2 from the water, heating the feed water and providing a water reservoir. (buffer function).

Which types of deaerators do we offer?

There are two main types of deaerators (or degassers): spray-type deaerators and tray-type deaerators. We can supply both types, depending on your needs and requirements. While the spray-type version is usually more versatile and powerful, designed as a single tank and combining storage and deaeration in one container, the tray-type deaerator is the more conservative and well-known design. It is used worldwide in two different variants, the "European" form with a vertical top tank mounted on the feed water storage tank and 4 or 5 fixed perforated trays or thieves as internals, and the "American" form with usually a horizontal top tank and several modularized stainless steel tray stacks with slots inside.

The spray-type Deaerator

Spray-type deaerator, with full deaeration in a vessel, internal spray area with ring-shaped spray plate.

The tray-type Deaerator

Tray-type deaerator, with dome or vertical tank on top of the feed water tank, which contains perforated trays to allow the water to trickle down in small streams and bring them into contact with the steam flowing upwards

Which type to choose?

In terms of performance, with all three designs, 7 ppb Oxygen content at the outlet is achievable. Hence, performance is not the prime criterion. What differs is initial price, flexibility, lifetime costs (spare parts), and ease of operation and installation.

Spray-type

Best solution for most situations

Low overall height (no top tank)

Easy installation, due to one vessel only, no top tank mounting, no added insulation

No wear parts, minimal spare part costs

Robust and highly reliable

Low steam loss (no vent condenser needed)

Condensate flow rates from 5 to 2000 tons per hour

Tray-Type (European Design)

Well known, conservative choice

Less pressure drop than spraytype on water side and steam side

Additional vertical stainless steel tank (column) on top of storage tank needed

Assembly of top tank and bottom tank on site (flanged connection usual, welded connection possible)

Condensate flow rates from 5 to 500 tons per hour

Tray-Type (American Design)

In ASME-regions and regions with strong US engineering influence the standard option.

Rarely used in Europe

Several stainless-steel rectangular tray-stack-modules in a horizontal top tank

Suitable for large condensate flows with low system steam pressure

Trays and sprayers are spare parts with regular exchange intervals.

Condensate flow rates from 5 to 2000 tons per hour.

The best designs,

with low production costs

Our secret: We know the best-priced vessel manufacturers in Eastern Europe and the Baltics, we know which vessel sizes they do best, and we know how to monitor their performance to achieve the best manufacturing results for the designs we calculated.

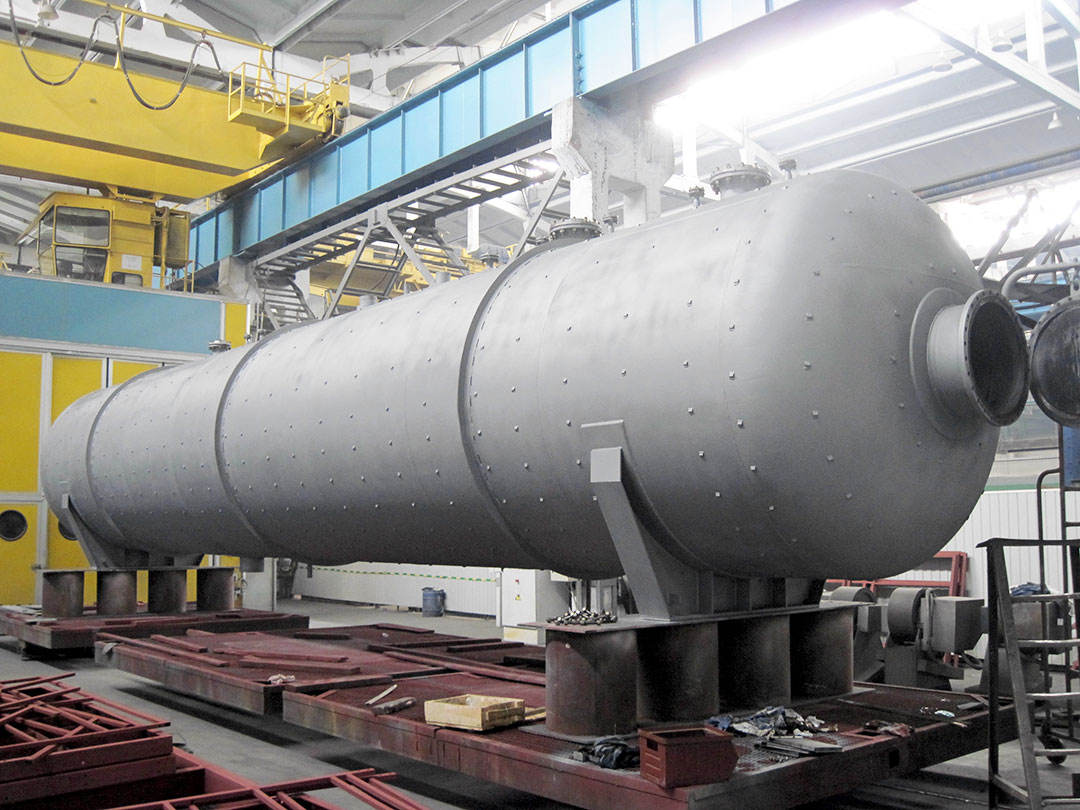

Close cooperation with Estanc

Our most frequent workshop partner has so far been our fellow Tallinn company Estanc, a pressure vessel workshop, which is the largest of its kind in the Baltics. It has modern facilities, is fully equipped to handle also large-diameter vessels, and both of our companies know each other well enough to work perfectly hand in hand for deaerator deliveries. Estanc is usually our first choice as a production location when we offer for a European destination.

Our team delivered more than 50 deaerators successfully together with Estanc in the past few years. We satisfied clients like Siemens, Hitachi Zosen Inova, Doosan, Sumitomo, Andritz, or Valmet.

We deliver more than just the deaerator

If you need local instrumentation, like a level gauge, pressure or temperature gauges or sensors, safety valves, or other auxiliary equipment, like vent condensers, vacuum ejectors, UV Lamps for disinfection, or other vessels like blowdown tanks and flash vessels, electrical heating coils or pump skids, we can offer a total package delivery.

If you need a deaerator for your system, please contact us. We find the ideally fitting design with you, and offer accordingly.